Thursday, August 22, 2013

Tuesday, August 20, 2013

Miter practice

I've been practicing mitering Linotype border using the Hammond glider saw. I almost took out a window here at Stumptown Printers when the miter vise clamp wasn't tight enough and a slug got away from me. Won't make that mistake again.

Monday, August 19, 2013

Proofing 10^440

Looking pretty clean so far. This type form will be used for a limited edition keepsake broadside celebrating 11 years of the Stumptown Printers' Arigato Pak.

Russian Made Linotype in Action

This is a great little video of a Russian made (?) line casting machine. Thanks to Bill Spurling for passing on the link. Check out the safety guard that flips into place over the mold and vise before casting.

Saturday, August 17, 2013

Linomite

I noticed a slight little build up of type metal on the pump plunger rod when I started casting this evening, and after a couple hours of casting lines this is what that build up became:

Linomite! It was enough to restrict the plunger from returning to its fullest upward position. Gotta keep an eye on this next time. I'm guessing that this happened because the pot was a bit too cool. I'll test the theory next time we cast. Otherwise, anyone out there have tips on how to prevent this?

Sunday, August 4, 2013

Ancient compositor's knot

This is a set of space bands lovingly tied up by an operator of the Stumptown Printer's model 31 long before we owned the machine. It's an example of marlinspike seamanship by an old Linotype salt. I hadn't had the heart (or need) to disrupt this tidy knot before today, but we needed the bands and so this is the documentation of the touch of a craftsman from years ago. We brought the bands to the C.C. Stern Type Foundry to use with the machine there. I believe that the old salt would approve.

Wednesday, June 5, 2013

Today's message to the model 31

I managed to get a couple lines off of the machine today, but printing, die cutting, hand bindery and prepress took the lion's share of shop time. I don't like to fire up the machine unless we have at least a handful if slugs to cast. Next time...

Tuesday, March 19, 2013

Handy Illustration of First-Elevator Cam

This illustration is a useful reference if you are in the back of the machine and cycling it by hand, and you need to know when to stop cycling(!) By looking at this cam, you can determine when the first elevator is resting on the vise cap, or when the justifications take place, etc. This illustration is scanned from the Intertype Book of Instruction, page 46.

The Trouble Line

Occasionally while running the machine, I've experienced a "no cast". This happened randomly, or at least it seemed to be random, because after a second attempt to cast the same line often the machine would give in and produce the slug. When it didn't cast a second time, I would switch it up slightly and maybe add a thin space, etc. and I could get it to go. It didn't happen frequently enough for me to explore the issue until recently. The line pictured above is the one that stopped me and got me to look into the problem.

In this case I was setting 10pt on 10pt mold, 18 pica width, first position. I was using standard justification with the hydraquadder off. As you can see, it's a full line, 6 space bands with less than a pica to go. I sent the same line through as it is pictured (but recreated with different matrices) several times. No go. Other lines that seemed to be similar length and spacing did go, so it was a mystery to me why this one would not.

More details to come....

Spot Color!

This makes use of 6pt Linotype Garamond, handset type, ornaments and found letterpress advertising cuts.

Monday, March 18, 2013

I'm in the process of tracking down belt material for the main drive belt. I stopped in on our local supplier Empire Rubber where the crew there presented me with a bunch of great info and options. Good guys and a good resource. With their help, I should be able to match the lacing and material.

Update:

The belt that I ended up using was:

Empire Rubber's item number: 20045012

Description: 4/140 II Tan FSxFS 1.5" W

Flexco Clipper Lace was used, added to trim length of 78.5"

Saturday, February 23, 2013

Friend Ivan Snyder giving the Linotype a go

Friend Ivan Snyder giving the Linotype a go a video by Stumptown Printers on Flickr.

Here's our pal Ivan Snyder sitting at the Stumptown Printers Linotype. This guy has volunteered more time, sweat, muscle, know-how, equipment, etc. to the current Portland printing community than any one I know. He has helped usher in a new generation of Portland letterpress printers who appreciate the real deal and love working with metal type. Thanks Ivan!

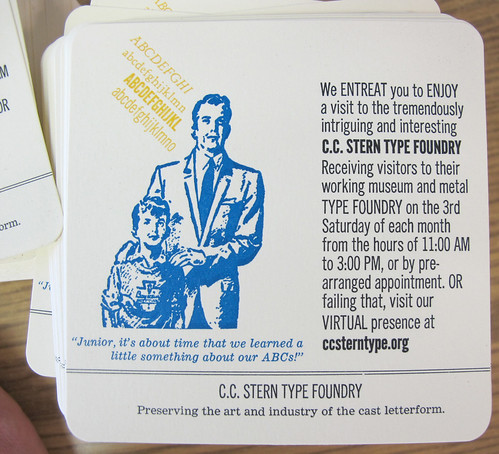

Promo For C.C. Stern Type Foundry

This is a promo piece for the C.C. Stern Type Foundry printed and cast here at Stumptown Printers before the foundry had its own Linotype model 31 which was donated by Bill Spurling of linotype.org

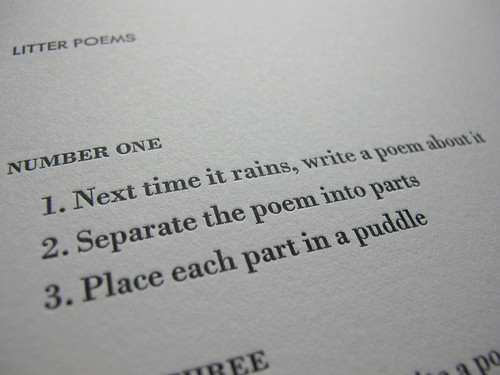

Close Up Of Litter Poems Proof 1

Another photo from our Flickr archives. These lines were cast shortly after rebuilding the keyboard (the first time). What a thrill to pull these proofs and get satisfactory results from the machine for the first time!

Bicycle Transportation Alliance pin packaging

Printing from slugs cast on our Linotype. Spartan Book 10pt and 12pt. Looks fairly clean here, but as I recall we had to spend a bit of time removing hairlines.

Wednesday, February 6, 2013

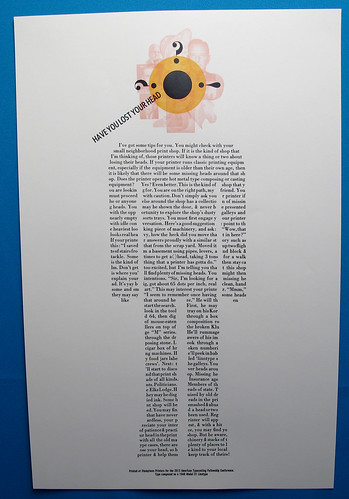

Linotype Man (Have you lost your head?)

Finished Print. Printed for the 2012 American Typecasting Fellowship Conference.

Linotype Man

Linotype form for "Have You Lost Your Head" broadside which was printed for the 2012 American Typecasting Fellowship Conference.

Subscribe to:

Posts (Atom)